The Tool/Dies are manufactured using latest CAD/CAM & VMC/Wire Cut facilities. All the Tool/Mould has been layout inspected and approved by QA before sending production process. We also provide technical support to its customers to develop cost saving and more efficient products design.

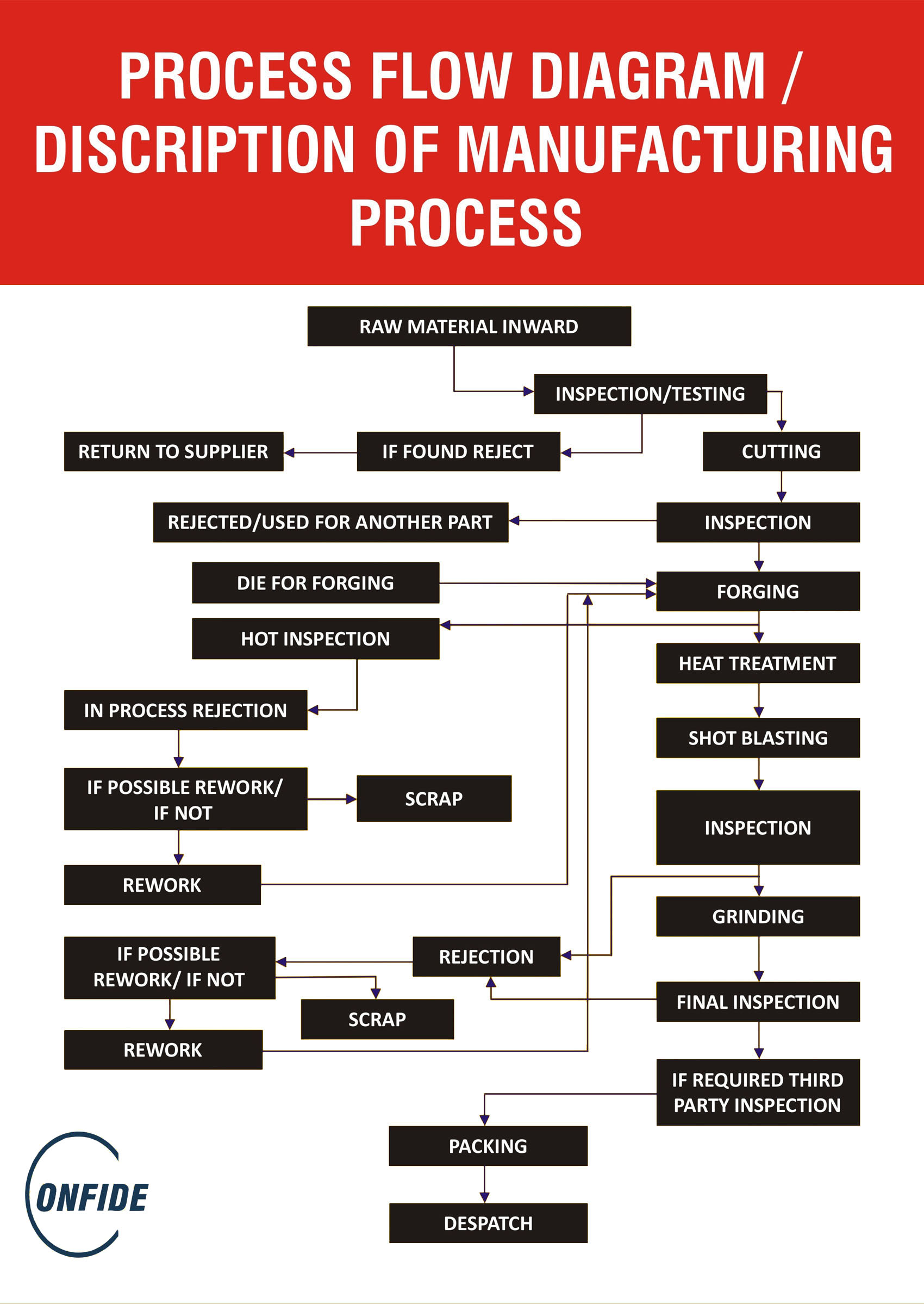

Raw Material Procured from Approved or Std Steel Mill and to be cut through Bandsaw Cutting and managed Lot wise Cut Pcs with specific color coding identification system and sent for next process lot Wise.

Cutting Material to be Heat with specific temperature as required according to metal grade in Billet Heating Induction. All furnaces having calibrated temperature controller and indicators.

After forging & Fettling Process material undergoes Heat Treatment as per the material specifications. Heat Treatment graphs & cycles are recorded and documented. Heat Treatment furnace and its Controlling instruments are NABL calibrated

After Heat Treatment & Shot Blasting all Forging are Inspected according to specifications and drawings & 100% visual inspection. Critical dimensions are 100% inspected before packing and shipment.

CFPL can also supply Forging in machined & Assembly condition as per requirement of customer. Forging can be also supplied with various type of surface treatment such as passivation, Electroplating, Blackening, powder coating, Zinc Platting, sand blasted, Glass bead blasted.